Abrasive Waterject Cutting

Abrasive Waterject Cutting

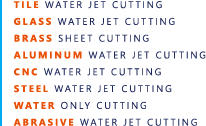

Abrasive Waterject Cutting is actually a cold cutting process which significantly differs from the other cutting methods that apply heat to the object that is to be cut. This technical process can profile any plate or sheet material ranging from aluminum to Titanium. Fundamentally, the abrasive waterjet cutting process is just the same as the water only cutting method except that after passing through the nozzle, the water enters a mixing chamber thereby creating a vacuum. Therefore, a controlled amount of abrasive is transferred into the jet stream. Since the cut quality of abrasive waterjet cutting is so precise and high, there is absolutely no need for post machining. Some of the striking benefits of abrasive waterjet cutting include the following. This technology can be used to cut a wide class of metals including aluminum, stainless steel, and brass without any tarnishing. This can be used to achieve intricate designs even on highly glossy and polished surfaces. In fact, using this method you can get ceramic tiles, granite, marble, slate, and limestone cut out to any of your designs.

Even laminates and composites can be cut without a trace of de-lamination. In this process we can cut Acrylic, Aluminium, Brass, Carbon Steel, Ceramics, Composites, Copper, Foils, Glass, Granite, Iron, Limestone, Marble, Nylon, Plastics, PVDF, Stainless Steel, Titanium & etc

WATERJET CUTTING SOLUTIONS

© 2023. copyrights Excel Waterjet . All Rights Reserved.Designed by Justsee