Composite Cutting

Composite Cutting

Composite Cutting

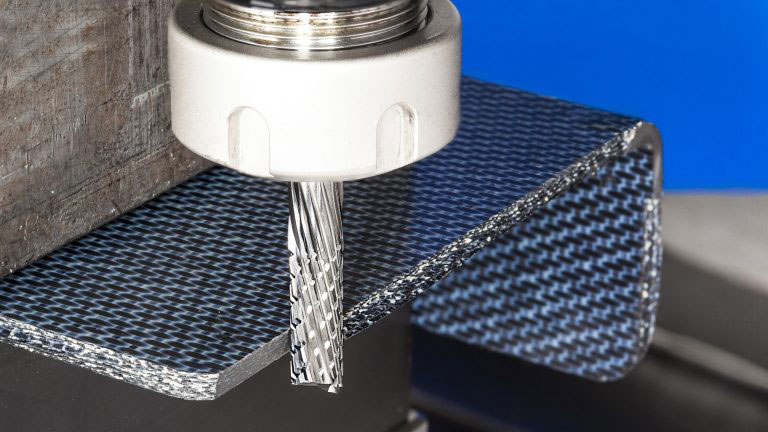

Reinforced for greater strength, Composites are heterogeneous materials whose cutting requires a different approach. Using conventional cutters and machining techniques the parts tend to wear out and require replacement.

As an alternative, cutting with a water jet offers a number of benefits for composite machining. They do not produce heat-affected zones (HAZ). The wastage of raw material is eliminated or minimal. The edges do not become rough nor are burrs formed. This makes Water Jet Cutting ideal for composites.

Advantages

- Create complex shapes using composites with precision water jet cutting

- NO Heat Affected Zone (HAZ) which is ideal for composites and more.

- Ideal for cutting up to 200 mm of composites materials depending on density of product.

- Eliminates most secondary finishing… no burrs or rough edges.

- Thick or thin, Water-Jet cutting is the most flexible cutting process for granite to foam.

- Minimal set up for automated cutting process and minimal downtime for quick seal change.

- Cuts without melting.

- Can pierce material directly without the need for a pre-drilled starter hole.

- One head for all applications, no guessing, no need to change bits.

Subscribe Newsletter

WATERJET CUTTING SOLUTIONS

© 2023. copyrights Excel Waterjet . All Rights Reserved.Designed by Justsee