Water Only Cutting

Water Only Cutting

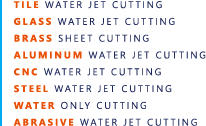

Waterjet cutting technology is a highly enhanced alternative to several other batch production methods including oscillating knife production and the conventional method of cutting employing expensive tooling. On account of the diameter of the jet, this process best suits the production of highly intricate cuttings including signage, flooring displays and ornate panels. Screen cutting, for instance can be achieved without burrs, discoloration or warping. This process can also be applied on all kinds of hardened materials. Water only cutting is highly useful to cut out creative designs without any discoloration to the cut edge. In fact, larger designs can be cut out in sections. The designs can be gathered from your art work or computer files. Even gasket, insulation materials, pre-printed, flexible materials, foam and rubber can be cut with parallel sides. This process is also highly suitable for prototypes and batch production involving huge quantities. In case of tube cutting, the job can be done without affecting the inner diameter. Since tooling is absolutely ruled out, there is an enormous amount of cost saving.In this process we can cut ABS, Carpet, Composites, Fibreglass, Foam, Mica, Leather, Plastics, Plywood, Polyethylene, PVC, Rubber, Silicone & Wood

WATERJET CUTTING SOLUTIONS

© 2023. copyrights Excel Waterjet . All Rights Reserved.Designed by Justsee